Chitsulo Chopangidwa ndi Kutentha Kwambiri Kupanikizika KwambiriKutsika kwa Torque Trunnion Chokwera Valavu ya Mpira China fakitale

Kodi valavu ya mpira wa trunnion yachitsulo yopangidwa ndi chiyani?

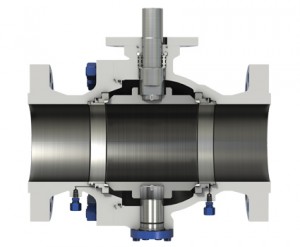

A Valavu ya mpira wa trunnion yopangidwa ndi chitsulozikutanthauza kuti mpirawo uli ndi ma bearing ndipo umaloledwa kuzungulira kokha, katundu wambiri wa hydraulic umathandizidwa ndi ma System contraindications, zomwe zimapangitsa kuti bearing pressure ikhale yochepa komanso kuti shaft isatope.

Kupanikizika kwa payipi kumayendetsa mpando wakumtunda motsutsana ndi mpira wosakhazikika kotero kuti kupanikizika kwa mzere kumakakamiza mpando wakumtunda kupita ku mpirawo kuti utseke. Kukhazikika kwa mpirawo kumatengera mphamvu yochokera ku kupsinjika kwa mzere, kuletsa kukangana kwakukulu pakati pa mpira ndi mipando, kotero ngakhale pa mphamvu yonse yogwira ntchito, mphamvu yogwirira ntchito imakhalabe yotsika. Izi zimakhala zabwino kwambiri ngati valavu ya mpira yayendetsedwa chifukwa imachepetsa kukula kwa actuator motero mtengo wonse wa phukusi la actuation la valve. Trunnion imapezeka pamitundu yonse komanso pamitundu yonse ya kupanikizika koma makamaka ndi ya kukula kwakukulu komanso mikhalidwe yopanikizika kwambiri.

Zinthu zazikulu za NORTECH Forged steel trunnion ball valve

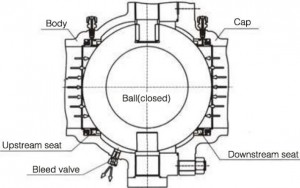

1. Kutseka kawiri ndi Kutuluka magazi (DBB)

Valavu ikatsekedwa ndipo dzenje lapakati likatulutsidwa kudzera mu valavu yotulutsira madzi, mipando yakumtunda ndi yakumunsi imatseka yokha. Ntchito ina ya chipangizo chotulutsira madzi ndi yakuti mpando wa valavu ungathe kuwonedwa ngati pali kutayikira panthawi yoyesa. Kuphatikiza apo, zotsalira mkati mwa thupi zimatha kutsukidwa kudzera mu chipangizo chotulutsira madzi. Chipangizo chotulutsira madzi chimapangidwa kuti chichepetse kuwonongeka kwa mpando chifukwa cha zinyalala zomwe zili mu sing'anga.

2. Mphamvu Yochepa Yogwira Ntchito

Valavu ya trunnion pipeline imagwiritsa ntchito kapangidwe ka trunnion ball ndi mpando wa valavu woyandama, kuti ichepetse mphamvu yamagetsi pansi pa kupanikizika kogwira ntchito. Imagwiritsa ntchito PTFE yodzipaka yokha ndi chitsulo chotsetsereka kuti ichepetse mphamvu ya friction kufika pamlingo wotsika kwambiri mogwirizana ndi mphamvu yayikulu komanso stem yopyapyala kwambiri.

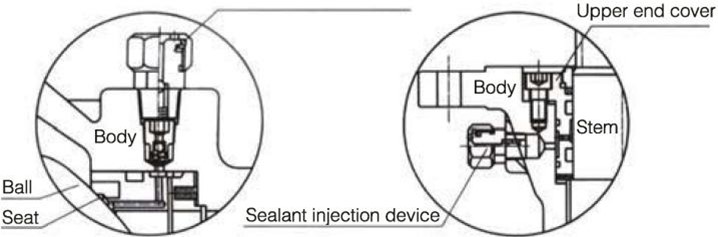

11. Tsinde Lotsimikizira Kuphulika

Tsinde limagwiritsa ntchito kapangidwe kake kosapsa. Tsinde lapangidwa ndi phazi pansi pake kuti poika chivundikiro chapamwamba ndi zomangira, tsindelo lisatuluke ndi cholumikizira ngakhale ngati mphamvu ya valavu yakwera modabwitsa.

Tsinde Loletsa Kuphulika

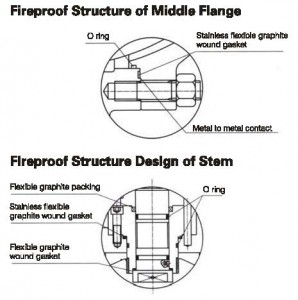

4. Kapangidwe ka Kapangidwe Kosapsa ndi Moto

Pakagwa moto pogwiritsa ntchito valavu, mphete ya mpando, mphete ya tsinde la O ndi mphete yapakati ya O yopangidwa ndi PTFE, labala ya zinthu zina zopanda chitsulo idzawonongeka kapena kuwonongeka kutentha kwambiri. Pakakakamizidwa ndi sing'anga, valavu ya mpira idzakankhira chosungira mpando mwachangu kupita ku mpira kuti mphete yosindikizira yachitsulo igwirizane ndi mpira ndikupanga kapangidwe kothandizira kosindikiza chitsulo kupita kuchitsulo, komwe kumatha kuwongolera bwino kutuluka kwa valavu. Kapangidwe kake kosagwira moto ka valavu ya payipi ya trunnion ikugwirizana ndi zofunikira mu API 607, API 6FA, BS 6755 ndi miyezo ina.

5. Kapangidwe kotsutsana ndi malo amodzi

Valavu ya mpira imapangidwa ndi kapangidwe kotsutsana ndi static ndipo imagwiritsa ntchito chipangizo chotulutsira magetsi osasunthika kuti ipange mwachindunji njira yosasunthika pakati pa mpira ndi thupi kudzera mu tsinde, kuti itulutse magetsi osasunthika omwe amapangidwa chifukwa cha kukangana panthawi yotsegula ndi kutseka mpira ndi mpando kudzera mu payipi, kupewa moto wophulika womwe ungayambitsidwe ndi static spark ndikuwonetsetsa kuti dongosololi ndi lotetezeka.

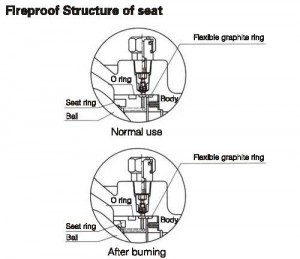

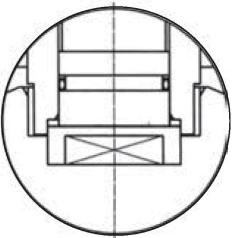

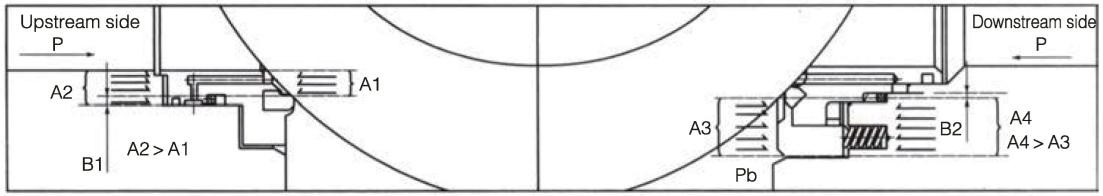

6. Kapangidwe kodalirika kosindikiza mpando

Kutseka mpando kumachitika kudzera m'malo awiri osungira mipando oyandama, Amatha kuyandama mozungulira kuti aletse madzi, kuphatikiza kutseka mpira ndi kutseka thupi. Kutseka mpando wa valavu motsika kumachitika chifukwa cha kukakamizidwa kwa kasupe. Kuphatikiza apo, mphamvu ya pisitoni ya mpando wa valavu imapangidwa bwino, zomwe zimapangitsa kuti kutsekedwa kwamphamvu kuchitike chifukwa cha kukakamizidwa kwa sing'anga yokha. Mitundu iwiri yotsatirayi ya kutseka mpira ikhoza kuchitika.

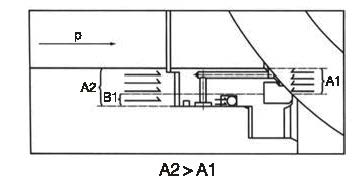

7. Kusindikiza Kamodzi

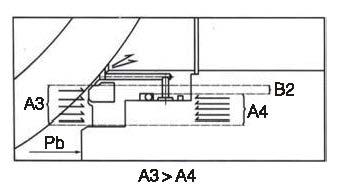

(Kuchepetsa Kupanikizika Kokha mu Khomo Lapakati la Valavu) Kawirikawiri, kapangidwe kamodzi kotseka kamagwiritsidwa ntchito. Ndiye kuti, pali kutseka kwapamwamba kokha. Pamene mipando yodziyimira payokha yodzaza ndi mipando yotsekera yokwera ndi yotsika imagwiritsidwa ntchito, khola lamkati la valavu lopanikizika kwambiri limatha kuthana ndi mphamvu yomangika ya kasupe, kuti mpando utuluke mu mpira ndikuchepetsa kupanikizika kokha kupita ku gawo lotsika. Mbali yakumtunda: Pamene mpando ukuyenda mozungulira pa valavu, kupanikizika "P" komwe kumachitika pa gawo lokwera (lolowera) kumapanga mphamvu yobwerera kumbuyo pa A1, Popeza A2 ndi yokwera kuposa A1, A2-A1=B1, mphamvu pa B1 idzakankhira mpando ku mpira ndikutseka gawo lokwera mwamphamvu.

Mbali ya pansi: Kupanikizika kwa "Pb" mkati mwa valavu Cavity kukakwera, mphamvu yomwe imagwiritsidwa ntchito pa A3 imakhala yokwera kuposa ya pa A4. Monga A3-A4=B2, kusiyana kwa kupanikizika pa B2 kudzagonjetsa mphamvu ya kasupe kuti mpando utuluke kuchokera ku mpira ndikuchepetsa kupanikizika kwa valavu kupita ku gawo la pansi pambuyo pake, mpando ndi mpira zidzatsekedwanso pansi pa mphamvu ya kasupe.

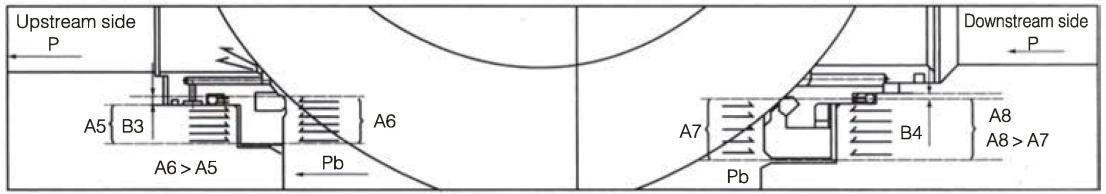

8. Kutseka Kawiri (Piston kawiri)

Valavu ya trunnion pipeline imatha kupangidwa ndi kapangidwe ka Sealing kawiri isanayambe komanso itatha mpira kuti ikwaniritse zofunikira zina zapadera komanso zofunikira kwa ogwiritsa ntchito. Ili ndi mphamvu ya piston iwiri. Munthawi yabwinobwino, valavu nthawi zambiri imagwiritsa ntchito sealing yoyamba. Pamene sealing yoyamba yawonongeka ndikuyambitsa kutayikira, mpando wachiwiri ukhoza kugwira ntchito yotseka ndikuwonjezera kudalirika kwa sealing. Mpando umagwiritsa ntchito kapangidwe kophatikizana. Sealing yoyamba ndi sealing yachitsulo kupita kuchitsulo. Sealing yachiwiri ndi fluorine rabara O ring yomwe ingatsimikizire kuti valavu ya mpira imatha kufika pamlingo wa thovu lotseka. Pamene kusiyana kwa kuthamanga kuli kochepa kwambiri, mpando wotseka udzakanikiza mpirawo kudzera mu kasupe kuti ukwaniritse kutseka koyamba. Pamene kusiyana kwa kuthamanga kukukwera, mphamvu yotseka ya mpando ndi thupi idzawonjezeka moyenera kuti itseke bwino mpando ndi mpira ndikuwonetsetsa kuti kutseka kukugwira ntchito bwino.

Kutseka koyamba: Kumtunda.

Ngati kusiyana kwa kuthamanga kuli kotsika kapena palibe kusiyana kwa kuthamanga, mpando woyandama udzayenda mozungulira pa valavu pansi pa kasupe ndikukankhira mpando ku mpira kuti usunge kutseka kolimba. Ngati mpando wa valavu uli wokwera kuposa mphamvu yomwe imagwiritsidwa ntchito pamalo A1,A2-A1=B1. Chifukwa chake, mphamvu mu B1 idzakankhira mpando ku mpira ndikutseka kolimba kwa gawo lakumtunda.

9. Chipangizo Chothandizira Chitetezo

Popeza valavu ya mpira imapangidwa ndi kutseka koyambirira ndi kwachiwiri komwe kumakhala ndi pistoni ziwiri, ndipo khonde lapakati silingathe kupulumutsa mphamvu zokha, valavu yotetezera iyenera kuyikidwa pathupi kuti ipewe kuopsa kwa kuwonongeka kwa mphamvu kwambiri mkati mwa khonde la valve komwe kungachitike chifukwa cha kutentha kwa sing'anga. Kulumikizana kwa valavu yotetezera nthawi zambiri kumakhala NPT 1/2. Mfundo ina yofunika kuikumbukira ndi yakuti cholumikizira cha valavu yotetezera chimatulutsidwa mwachindunji mumlengalenga. Ngati kutulutsa mwachindunji mumlengalenga sikuloledwa, tikupangira kuti valavu ya mpira yokhala ndi kapangidwe kapadera kothandizira mphamvu zokha kupita kumtsinje wapamwamba iyenera kugwiritsidwa ntchito. Onani zotsatirazi kuti mudziwe zambiri. Chonde lembani motsatira dongosolo ngati simukufuna valavu yotetezera kapena ngati mukufuna kugwiritsa ntchito valavu ya mpira yokhala ndi kapangidwe kapadera kothandizira mphamvu zokha kupita kumtsinje wapamwamba.

Chojambula chachikulu cha valavu ya mpira kumtunda ndi pansi pake

Chithunzi chachikulu cha mpumulo wa kuthamanga kwa valavu ya mpira kupita ku kutseka kwa mtsinje wapamwamba ndi pansi pa mtsinje

12. Kukana dzimbiri ndi kukana kupsinjika kwa sulfide

Pali njira zina zochotsera dzimbiri zomwe zimatsalira pa makulidwe a khoma la thupi.

Tsinde la chitsulo cha kaboni, shaft yokhazikika, mpira, mpando ndi mphete ya mpando zimayikidwa ndi nickel plating ya mankhwala motsatira ASTM B733 ndi B656. Kuphatikiza apo, zinthu zosiyanasiyana zosagwira dzimbiri zimapezeka kuti ogwiritsa ntchito asankhe. Malinga ndi zosowa za makasitomala, zida za valavu zitha kusankhidwa motsatira NACE MR 0175 / ISO 15156 kapena NACE MR 0103, ndipo kuwongolera kwambiri khalidwe ndi kuwunika kwabwino kuyenera kuchitika panthawi yopanga kuti zikwaniritse zofunikira mu miyezo ndikukwaniritsa zofunikira pantchito m'malo okhala ndi sulfure.

Mafotokozedwe a valavu ya mpira wa NORTECH Forged steel trunnion

Mafotokozedwe Aukadaulo a Trunnion Ball Valve

| M'mimba mwake mwa dzina | 2”-56”(DN50-DN1400) |

| Mtundu Wolumikizira | RF/BW/RTJ |

| Muyezo wa kapangidwe | Valavu ya mpira ya API 6D/ASME B16.34/API608/MSS SP-72 |

| Zinthu zakuthupi | Chitsulo chopangidwa/Chitsulo chosapanga dzimbiri chopangidwa/Chitsulo chosapanga dzimbiri chopangidwa/Chitsulo chosapanga dzimbiri chopangidwa |

| Zida za mpira | A105+ENP/F304/F316/F304L/F316L |

| Zipangizo za mpando | PTFE/PPL/NAYLON/PEEK |

| Kutentha kogwira ntchito | Kufikira 120°C pa PTFE |

|

| Kufikira 250°C pa PPL/PEEK |

|

| Kufikira 80°C pa nylon |

| Mapeto a Flange | ASME B16.5 RF/RTJ |

| Mapeto a BW | ASME B 16.25 |

| Maso ndi maso | ASME B 16.10 |

| Kutentha kwa kuthamanga | ASME B 16.34 |

| Chitetezo cha moto & chotsutsana ndi malo amodzi | API 607/API 6FA |

| Muyezo woyendera | API598/EN12266/ISO5208 |

| Umboni wowonetsa | ATEX |

| Mtundu wa ntchito | Bokosi la giya lamanja/choyendetsa magiya a Pneumatic/choyendetsa magetsi |

Chiwonetsero cha Zamalonda: Valavu ya mpira wa trunnion yopangidwa ndi chitsulo

Kugwiritsa ntchito valavu ya mpira wachitsulo chopangidwa ndi NORTECH

Mtundu uwu waValavu ya mpira wa trunnion yopangidwa ndi chitsuloimagwiritsidwa ntchito kwambiri pakugwiritsa ntchito, kuyeretsa ndi kunyamula mafuta, gasi ndi mchere. Ingagwiritsidwenso ntchito popanga mankhwala, mankhwala; njira yopangira magetsi amadzi, mphamvu ya kutentha ndi mphamvu ya nyukiliya; njira yotulutsira madzi,